Roll-to-Roll Atomic Layer Deposition

Roll-to-Roll Atomic Layer Deposition

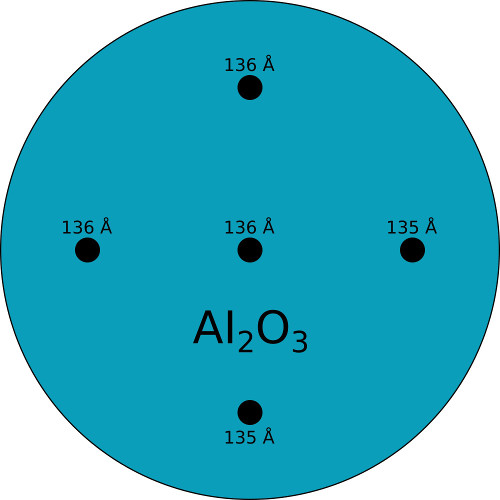

The roll-to-roll (R2R) plasma-enhanced atomic layer deposition (PEALD) system is designed for the continous processing of flexible substrates and inline multilayer ALD coating on glass panels. The system addresses the need for high-throughput, uniform, and conformal thin film dpeosition on flexible materials, which is critical for applications such as flexible electronics, displays, barrier coatings, and panels. NANO-MASTER's patented continuous flow process doubles the throughput of traditional ALD systems.

A few key advantages of roll-to-roll PEALD are:

- Roll-to-roll substrate handling

- ECR enhanced hollow cathode source

- Onboard precursor delivery w/ fast pulse delivery valves

- Fully automated PC based, recipe driven

- Computer controlled safety interlocks

- LabVIEW user interface

- Options

- Flexible electronics

- Barrier coatings for packaging

- Photovoltaic cells

- Sensors and actuators