Etching

Reactive Ion Etching

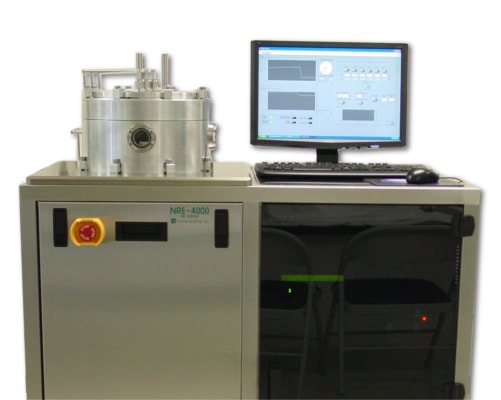

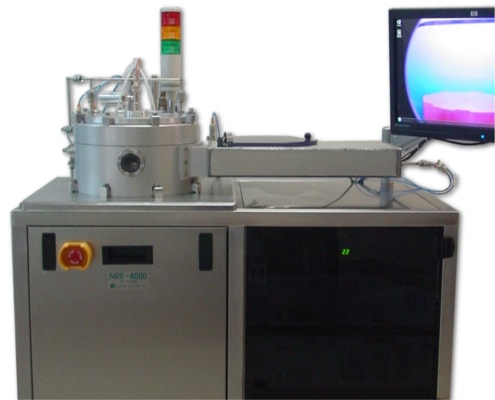

The NRE-4000 is a stand alone Reactive Ion Etching (RIE) system with shower-head gas distribution and water cooled RF platen. It has a stainless steel cabinet and a 13" cylindrical Aluminum chamber that opens from top for wafer loading. Chamber has two ports, one with a 2" window the other with a blank off for end point detection and for other diagnostic. It can accept up to 12" (300 mm) wafers. Chamber is extremely clean in design and reaches 10-6 Torr or lower base pressure depending on the pumping package. It can be operated in the pressure range of 20 mTorr to 8 Torr. Pumping package consists of a throttle valve, 250 l/sec corrosive turbomolecular pump, sieve filter, and a 10cfm mechanical pump with fomblin oil. The RF power is provided by 600 W 13.5 MHz power supply, and auto-tuner. The self DC bias is continuously monitored and reaches as high as -500 V which is important for anisotropic etching. The system is completely automated and is PC controlled. The real time system pressure and DC bias is displayed in graphic format while flow and power is displayed in alpha numeric format. Four levels of authorization Auto, Engineering, Process and Maintenance prevents unauthorized use of the system while giving maximum flexibility to user for setting up recipes in Process mode and running in Auto mode with high reproducibility.

View MoreDeep Reactive Ion Etching

NANO-MASTER DRIE systems incorporate a planar ICP source for high density plasma generation. Our systems have the ability to be used both with Cryo etch and Bosch processes that can create deep penetration, steep-sided holes and trenches in wafers with high aspect ratios.

View MoreIon Beam Milling

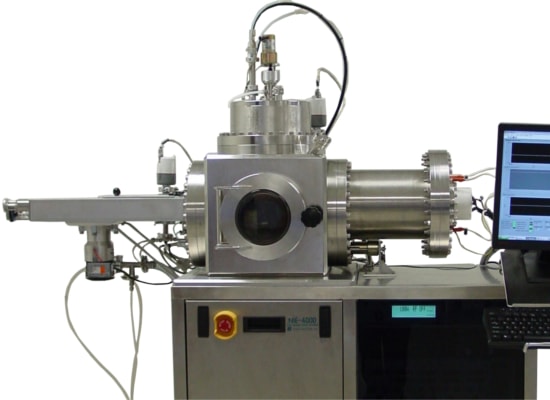

Etching of metals which do not have volatile compounds such as Cu, Au cannot be accomplished in RIE systems. On the other hand, physical etching with accelerating Ar ions is possible. Typically surface is patterned with thick resist for masking, and the energetic ion flux during etching overheats the substrate and the resist. Unless efficient means of removing the heat is found resist becomes very difficult to remove.

NANO-MASTER technology has demonstrated capability of keeping substrate temperature below 50 °C along with wafer rotation to achieve the desired uniformity which makes it possible to etch wafers with resist pattern.

View MoreHybrid PAALE & PEALD

The NANO-MASTER NLE-4000 is a stand-alone hybrid PAALE/PEALD system for performing plasma-enhanced atomic layer deposition (PEALD) as well as plasma-assisted atomic layer etching (PAALE). Both processes can be performed in a single chamber without any mechanical reconfiguration.

View More