Deposition

E-Beam Evaporation

The Electron Beam Evaporation System can come in a compact vertical dual chamber configuration consisting of the 16” cube main chamber where platen is located and a secondary chamber for housing the e-beam source. This configuration can be provided with a gate valve between the two chambers to be used as a load lock to keep the e-beam source and the evaporation pockets in vacuum while substrate is loaded and unloaded from the main chamber. On other applications where automatic loading and unloading of wafer is needed, a third load lock chamber is attached to the left face of the cube. In this case, the main chamber can be kept at low 10-7 Torr range at all times, and wafer loading to start of the evaporation can be less than few minutes.

View MorePECVD

NANO-MASTER's PECVD systems are capable of depositing high quality SiO2, Si3N4, CNT, DLC or SiC films on up to 8" diameter substrate sizes. Depending on applications many different plasma sources can be used which include: RF shower head electrode, Hollow Cathode RF plasma source, ICP plasma source or Microwave plasma source. Substrate platen can accommodate up to 8" wafers and can be biased with RF, Pulsed DC, or DC while being heated up to 800°C resistively or with IR lamps and cooled with chilled water. The chamber is evacuated to low 10-7 torr pressure range using 250 l/sec turbo molecular pump backed with 5 cfm mechanical pump. The systems are automated fully with PC control.

View More

Sputtering

NANO-MASTER's state-of-the-art Sputtering Systems can be constructed with various chamber and source configurations to efficiently deposit metal and dielectric thin films on to substrates up to 200mm. The systems can be equipped with DC, RF and Pulsed DC power supplies to enable sequential or co-sputtering. The systems are pumped with a turbomolecular pumping package to achieve a base pressure of 5x10-7 Torr. Magnetron to substrate distance is adjustable in order to achieve desired uniformity and deposition rate. Rotating platen with off axis magnetrons provide means of achieving the best film uniformity. Crystal thickness monitor is provided for terminating process automatically. Substrate holders can be heated up to 800°C while rotating and RF biased.

View MoreThermal Evaporation

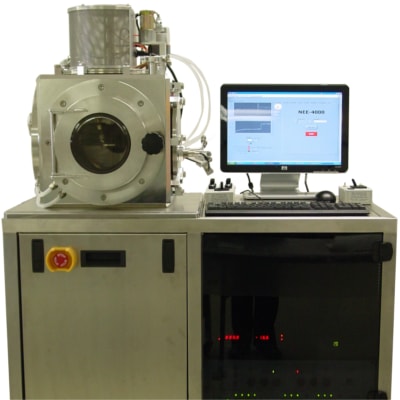

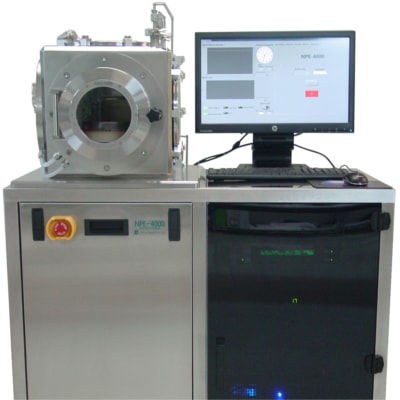

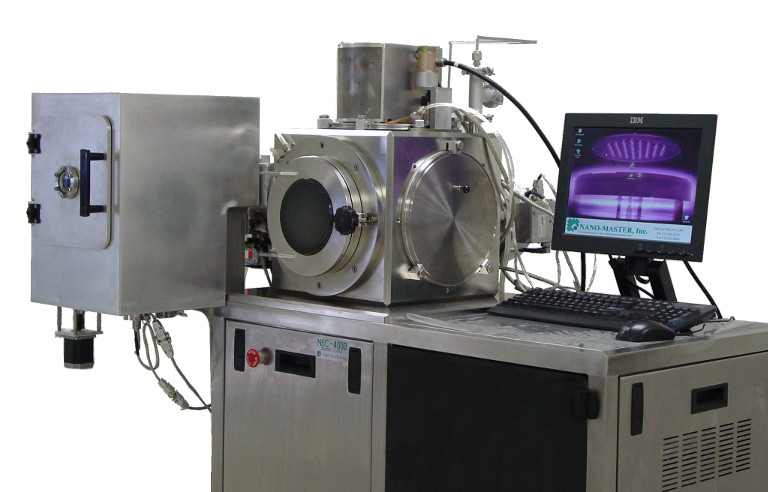

NANO-MASTER's NTE-3000 is a PC controlled Stand Alone thermal evaporator system with wide ranges of applications in organic to metal evaporation. It is designed with extreme care to achieve clean, uniform, controllable and reproducible process on a small footprint. It provides a low cost, high quality and advanced capability to end users with demanding applications in R&D and low scale manufacturing. NTE-3000 operates either at a set RMS current or in a closed loop configuration and in this case the variation of the deposition rate is used to adjust RMS current to maintain constant deposition rates.

The NTE-4000 is a stand alone thermal evaporator system allowing more room for additional capabilities such as co-evaporation, dual evaporation and sputtering capabilities.

View More