Growth

ALD

Atomic Layer Deposition is an important technique for depositing thin films for a variety of applications. ALD is able to meet the needs for precise thickness control and conformal deposition in high aspect ratio structures to a level that far exceeds other deposition techniques. The nature of the sequential, self-limiting surface reactions in ALD produces a non statistical deposition because the randomness of the precursor flux is not a factor. As a result, ALD films remain extremely smooth, continuous, and pin-hole free allowing for excellent film properties. ALD processing can also be scaled to very large substrates.

View MorePA-MOCVD

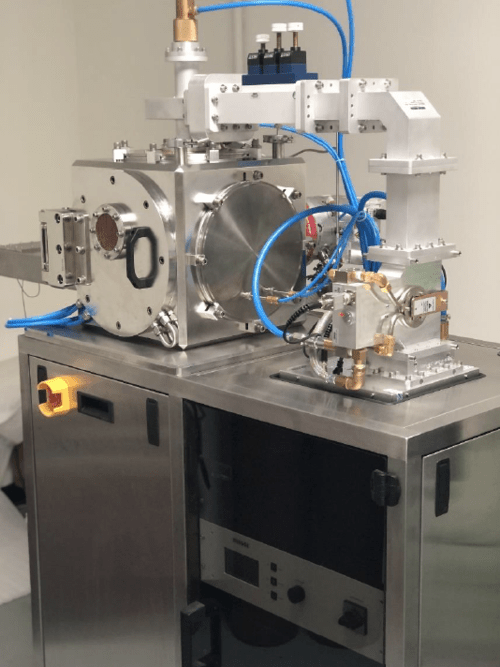

NANO-MASTER, Inc. has developed the first Table Top Plasma Assisted Metal Organic Chemical Vapor Deposition (PA-MOCVD) system for InGaN and AlGaN deposition processes. The features include five bubblers with individual cooling baths, heated gas lines, 950°C platen, three gas rings, RF plasma source with Shower Head Gas Distribution and N2 flush at the end of the process, 5 10-7 Torr base pressure, 250 l/sec turbo pump with oil-free scroll pump, PC controlled, fully automated and safety interlocked.

View More

MW-PECVD

NANO-MASTER has developed a MW-PECVD (Microwave-PECVD) for depositing single and plycrystalline diamonds. The NMP-4000 is a stand alone, PC controlled MW-PECVD system with LabVIEW software featuring three levels of password-controlled user authorization. The system is fully automated, and safety-interlocked. Automatic PC control of recipes, flows, and pump-down/vent cycles. Options include automatic load-unload, gas bubblers, MFCs's, etc.

View MoreHybrid PECVD/PEALD

NANO-MASTER has developed a hybrid PECVD/PEALD system within the same chamber. The NANO-MASTER NLP-4000 is a stand-alone hybrid PECVD/PEALD system for performing plasma-enhanced atomic layer deposition (PEALD) as well as plasma-enhanced chemical vapor deposition (PECVD). Both processes can be performed in a single chamber without any mechanical reconfiguration. It is also capable of depositing a stack of layers of PEALD/PECVD in the same process. It is CE and SEMI Standards-compliant and capable of processing up to 8” wafers. The system is controlled with LabVIEW software and features three-level password-controlled user authorization using a touch-screen monitor. The system is fully automated, safety-interlocked, recipe-driven, with status indicators and graphic and alphanumeric displays.

View More