PVD

E-Beam Evaporation

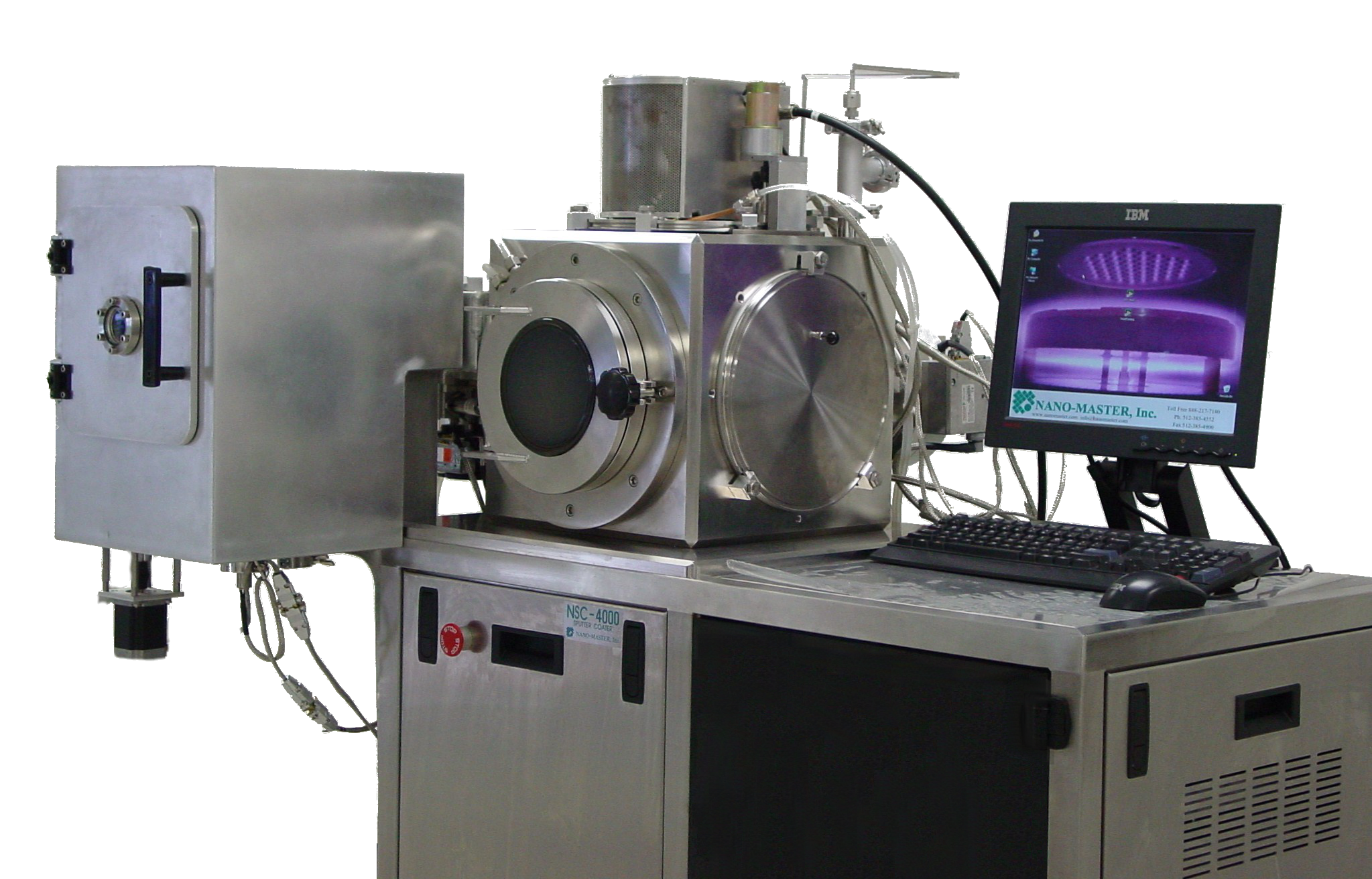

NANO-MASTER's' NEE-4000 Electron Beam Evaporation Systems come in a dual chamber configuration consisting of the main chamber where platen is located and a secondary chamber for housing the e-beam source. This configuration with a gate valve between two chambers may be used as a load lock to keep the e-beam source pockets in vacuum while substrate is loaded and unloaded from the main chamber substrate holder or platen. On other applications where automatic loading and unloading of wafers is needed, it can be achieved through a third load lock chamber that may be attached to the left face of the cube. Co-evaporation capability with multiple e-beam sources and ability to program compositions or compositional gradients through PC control can be provided.

View MoreThermal Evaporation

NANO-MASTER's NTE-3000 is a PC controlled table top thermal evaporator system with wide ranges of applications in organic to metal evaporation. It is designed with extreme care to achieve clean, uniform, controllable and reproducible process on a small footprint. It provides a low cost, high quality and advanced capability to end users with demanding applications in R&D and low scale manufacturing. NTE-3000 operates either at a set RMS current or in a closed loop configuration and in this case the variation of the deposition rate is used to adjust RMS current to maintain constant deposition rates.

The NTE-4000 is a stand alone thermal evaporator system allowing more room for additional capabilities such as co-evaporation, dual evaporation and sputtering capabilities

View MoreSputtering

NANO-MASTER's NEE-4000 Electron Beam Evaporation Systems come in a dual chamber configuration consisting of the main chamber where platen is located and a secondary chamber for housing the e-beam source. This configuration with a gate valve between two chambers may be used as a load lock to keep the e-beam source pockets in vacuum while substrate is loaded and unloaded from the main chamber substrate holder or platen. On other applications where automatic loading and unloading of wafers is needed, it can be achieved through a third load lock chamber that may be attached to the left face of the cube. Co-evaporation capability with multiple e-beam sources and ability to program compositions or compositional gradients through PC control can be provided.

View More